Contents

This article dives deep into the world of rack mount cases, exploring their various types, features, and applications. From 4U to smaller 2U and larger options, we’ll cover how these cases provide robust protection for your valuable equipment, whether you’re rolling it across a stage or shipping it across the country. This article is worth reading because it offers a comprehensive guide to choosing the right rackmount case for your needs, helping you safeguard your investment and ensure seamless operation, wherever your equipment needs to roll.

1. What is a Rackmount Case and Why Do You Need One?

A rackmount case is a specialized enclosure designed to house and protect electronic equipment that conforms to the standard 19-inch rack format. This format is widely used for mounting various types of equipment, including servers, audio/video gear, networking devices, and industrial control systems. A rackmount case provides a secure and organized way to transport, store, and operate this equipment. The case can come in many sizes, for example a 4U or 2U case. The rackmount case can also be called a rack case.

Rack mount cases are essential for anyone who needs to transport or protect their valuable rackmount equipment. Here’s why:

- Protection: Rackmount cases are designed to protect sensitive electronics from physical damage during transport and handling. They shield equipment from impacts, shocks, vibration, and the elements.

- Organization: They provide a standardized way to mount and organize multiple pieces of equipment in a single, portable unit. This simplifies setup, teardown, and transport.

- Durability: Rackmount cases are typically built from robust materials like steel, aluminum, or high-impact plastics, ensuring they can withstand the rigors of travel and frequent use.

- Security: Many rackmount cases come with locking features to secure your equipment and prevent unauthorized access.

- Portability: Rackmount cases often feature handles, wheels, and other features that make them easy to transport from one location to another. Some have a pull handle.

Whether you’re a musician, AV technician, IT professional, or involved in any field that relies on rackmount equipment, a rackmount case is a crucial investment for protecting your gear and ensuring its reliable performance. You can choose a compact case if needed.

2. What are the Different Sizes and Types of Rackmount Cases?

Rackmount cases come in various sizes and types to accommodate different needs and equipment. The size of a rackmount case is typically specified in rack units (U), where 1U equals 1.75 inches in height.

Common Sizes:

- 1U Rackmount Case: The smallest standard size, suitable for shallow equipment like patch panels, small switches, or audio interfaces.

- 2U Rackmount Case: Offers more vertical space than 1U, accommodating a wider range of equipment, including some servers, audio processors, and power amplifiers. It is a good option if you need a compact case.

- 3U Rackmount Case: Provides even more space than 2U, making it suitable for larger equipment or multiple smaller devices. This is a compact option that is also very useful.

- 4U Rackmount Case: A popular size for a variety of equipment, including servers, larger audio mixers, and video switchers. This size is great if you need more space.

- Larger Sizes (5U, 6U, 8U, 10U, 12U, and beyond): Used for housing larger equipment or multiple smaller units. Larger cases can be used for storage as well.

Types of Rackmount Cases:

- Standard Rack Cases: These cases have a fixed rack frame inside, providing a secure mounting point for your equipment. They are typically made of steel or aluminum and may have removable front and rear lids. The rack frame is very strong.

- Shock Mount Rack Cases: Designed for maximum protection of sensitive equipment, shock mount cases feature an inner rack frame that is suspended within the outer case using shock mounts. These mounts absorb shocks and vibration during transport, protecting the equipment from damage. These shock mounts are often made from rubber.

- Mixer Cases: Specifically designed for audio mixers, these cases often have a slanted top section to provide easy access to the mixer’s controls. They may also have additional compartments for accessories.

- Rolling Rack Cases: These cases come equipped with wheels (often called casters) and a retractable handle, making them easy to transport heavy equipment.

- Lightweight Rack Cases: Constructed from lighter materials to make them easier to carry.

Choosing the right size and type of rackmount case depends on the dimensions and weight of your equipment, the level of protection required, and your specific transportation needs. The different case features are all useful.

3. What is the Difference Between a Shock Mount and Standard Rack Case?

The primary difference between a shock mount rack case and a standard rack case lies in the level of protection they offer against shocks and vibration.

Standard Rack Case:

- Construction: A standard rack case has a rigid rack frame directly attached to the outer shell of the case.

- Protection: While it provides good protection against impacts and scratches, it offers minimal protection against shocks and vibration. Any impacts or vibrations experienced by the case are directly transmitted to the equipment mounted inside.

- Applications: Suitable for transporting equipment that is not overly sensitive to shock and vibration, or when the case will be transported in a relatively stable environment.

Shock Mount Rack Case:

- Construction: A shock mount rack case features an inner rack frame that is suspended or “floated” within the outer case using shock mounts. These mounts are typically made of rubber or other elastomeric materials. They are made to absorb and dampen shocks.

- Protection: The shock mounts act as shock absorbers, isolating the inner rack frame and the mounted equipment from external shocks and vibration. This provides superior protection for sensitive electronics during transport. The shock mounts will protect your equipment.

- Applications: Ideal for transporting delicate equipment that is susceptible to damage from shock and vibration, such as sensitive measuring instruments, scientific equipment, or high-end audio gear. They are also preferred when the case may be subjected to rough handling or transported over uneven surfaces.

Here’s a table summarizing the key differences:

| Feature | Standard Rack Case | Shock Mount Rack Case |

|---|---|---|

| Rack Frame | Rigidly attached to the outer case | Suspended within the outer case using shock mounts |

| Shock Protection | Minimal | High |

| Vibration Protection | Minimal | High |

| Equipment Sensitivity | Suitable for less sensitive equipment | Ideal for delicate and sensitive equipment |

| Cost | Generally less expensive | Generally more expensive due to the added complexity of the shock mount system |

| Weight | Lighter, typically made of lightweight materials. | Heavier due to the additional shock mounts and sometimes more robust construction. |

| Applications | General transport, stable environments | Transport of sensitive electronics, rough handling, uneven surfaces |

| Protection | Protect from impact and scratches. | Protect from impact, scratches, shock and vibration. |

| Frame | Steel or aluminum frame attached to outer case. | Inner rack frame is suspended by shock mounts. |

In essence, if you need maximum protection for your sensitive equipment against the hazards of shock and vibration during transport, a shock mount rack case is the better choice. If your equipment is less sensitive or will be transported in a more controlled environment, a standard rack case may suffice.

4. Key Case Features to Consider When Choosing a Rackmount Case?

When selecting a rackmount case, several key case features should be considered to ensure it meets your specific needs:

- Rack Unit (U) Size: Choose a case with enough rack units (U) to accommodate all your equipment, with some extra space for future expansion if needed. Remember that 1U equals 1.75 inches in height.

- Depth: Rackmount cases come in various depths. Ensure the case is deep enough to accommodate your deepest piece of equipment, including any cabling or connectors at the rear.

- Lid Style: Some cases have removable front and rear lids, while others have a single lid or a hinged door. Removable lids offer easy access to both the front and rear of your equipment.

- Mounting Rails: Check the type of mounting rails used in the case. Most cases use threaded rails, but some use square-hole rails that require cage nuts. Ensure the rails are compatible with your equipment. Some cases will have a rack frame made of steel.

- Hardware: Inspect the quality of the hardware, including latches, handles, and corners. Look for heavy-duty steel latches and reinforced corners for added durability. Some cases will have a pull handle.

- Casters/Wheels: If you’ll be transporting the case frequently, consider a model with built-in casters or wheels. Ensure the wheels are durable and can support the weight of your equipment. Some cases will have a caster option.

- Ventilation: Proper ventilation is crucial for preventing overheating. Look for cases with vents or perforations to allow for airflow. Some models may have built-in fans for active cooling. You need to keep your components cool.

- Cable Management: Some cases offer features to help with cable management, such as built-in cable channels or tie-down points. This can help keep your rack organized and improve airflow.

- Security: If security is a concern, choose a case with locking latches or provisions for adding padlocks.

By carefully considering these case features, you can select a rackmount case that provides the right balance of protection, accessibility, and convenience for your specific application.

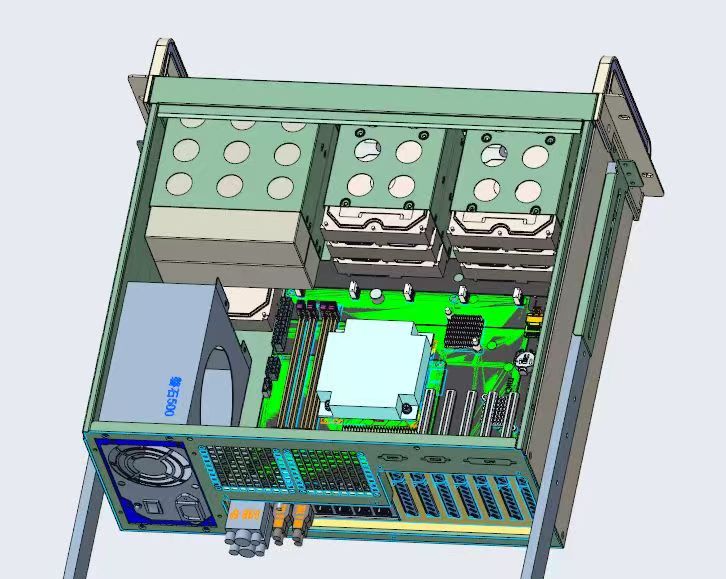

5. What are the benefits of using a 4U rackmount case?

A 4U rackmount case offers several advantages, making it a popular choice for a variety of applications:

- Ample Space: With a height of 7 inches (4 x 1.75 inches), a 4U case provides ample space for housing a significant amount of equipment. This makes it suitable for more complex setups that involve multiple devices or larger components.

- Expandability: The larger size of a 4U case allows for greater expandability. You can fit more equipment into a 4U case than smaller alternatives. It can accommodate a larger number of add-in cards, storage drives, or other peripherals, allowing you to upgrade your system as needed.

- Cooling: The increased internal volume of a 4U case allows for better airflow and cooling. There’s more room for larger or multiple fans, and the larger space helps dissipate heat more effectively. This is particularly important for high-performance systems that generate significant heat. The 4U case will help to keep components cool.

- Component Compatibility: 4U cases are generally compatible with a wider range of components, including larger power supplies, extended ATX motherboards, and full-height expansion cards.

- Storage Options: 4U cases often provide more options for storage. They might include multiple 3.5 inch or 5.25 inch drive bays, or even dedicated 2.5 inch bays for SSDs. The extra bay space makes the 4U a good option.

- Easier Maintenance: The larger size of a 4U case can make installation, maintenance, and upgrades easier. There’s more room to work inside the case, making it easier to access components and manage cables.

Here are some examples of 4U chassis:

| Model | 5.25" Bays | 3.5" Bays | 2.5" Bays | Fans |

|---|---|---|---|---|

| OCS4680-H24-H | 0 | 24(or 2.5") | 24(or 3.5") | 3*12038 (max:4) |

| OCS4680-H16-H | 0 | 16(or 2.5") | 16(or 3.5") | 3*12038 (max:4) |

| OCS4480-H8-F | 0 | 12(or 2.5") | 12(or 3.5") | 2*8038 |

| OCS4650-H20-F | 1(Optional) | 20(or 2.5") | 20(or 3.5") | 3*12038 ,2*8038 |

While 4U cases are larger and heavier than smaller alternatives, their advantages in terms of space, expandability, cooling, and component compatibility make them a great choice for many rackmount applications. They are an ideal option for a rackmount case.

6. What are the benefits of using a 2U rackmount case?

A 2U rackmount case, with a height of 3.5 inches (2 x 1.75 inches), offers a balance between compactness and functionality. Here are some of its key benefits:

- Space Efficiency: 2U cases are relatively compact, making them ideal for environments where rack space is limited. They allow you to maximize the density of your rack by fitting more equipment into a smaller vertical footprint. This is a major feature of a 2U case.

- Versatility: While smaller than 4U cases, 2U cases can still accommodate a wide range of equipment, including many servers, network appliances, and audio/video gear. They strike a good balance between size and functionality for many applications.

- Cooling: Although they have less internal volume than 4U cases, 2U cases can still provide adequate cooling for many types of equipment. They typically have space for multiple fans, and careful design can ensure sufficient airflow. However, you need to be mindful of the temperature inside.

- Cost-Effective: 2U cases are often more cost-effective than larger alternatives, both in terms of the case itself and the associated shipping costs.

- Standardization: The 2U form factor is a widely adopted standard in the industry, meaning there’s a large selection of compatible equipment and accessories available from various manufacturers.

Here are some examples of 2U chassis:

| Model | 5.25" Bays | 3.5" Bays | 2.5" Bays | Fans |

|---|---|---|---|---|

| OCS2700-H04-H | 0 | 0 | 4 | 3*8038 (max:4) |

| OCS266-8B-W | 1(Optional) | 8(or 2.5") | 8(or 3.5") | 3*8038 (max:4) |

| OCS2680-H12-H | 0 | 12(or 2.5") | 12(or 3.5") | 3*8038 (max:4) |

| OCS2480-H4-F | 0 | 4(or 2.5") | 4(or 3.5") | 3*8038 |

2U rackmount cases are a popular choice when a balance of compactness, functionality, and cost-effectiveness is needed. They are suitable for a wide range of applications and offer a good compromise between space efficiency and equipment compatibility.

7. How to Choose the Right Size Rackmount Case for Your Equipment?

Selecting the correct size rackmount case is crucial for ensuring your equipment fits properly and functions reliably. Here’s a step-by-step guide:

- Measure Your Equipment: Carefully measure the height, width, and depth of each piece of equipment you intend to mount in the rack case. Pay close attention to the height in rack units (U), where 1U = 1.75 inches.

- Calculate Total Rack Units: Add up the rack unit (U) requirements of all your equipment. For example, if you have a 2U server, a 1U switch, and a 1U patch panel, you’ll need a minimum of 4U of rack space.

- Consider Future Expansion: It’s always a good idea to choose a case with some extra space for future expansion. This will save you the hassle and expense of replacing the entire case if you need to add more equipment later.

- Account for Depth: Don’t forget to consider the depth of your equipment. Rackmount cases come in various depths, so make sure the case you choose is deep enough to accommodate your deepest piece of equipment, including any cabling or connectors at the rear. Most cases are 19 inches wide.

- Ventilation and Cooling: Consider the cooling requirements of your equipment. High-performance equipment generates more heat and may require a larger case with better ventilation or more space for fans. Ensure your components will stay cool.

- Weight Capacity: Check the weight capacity of the rackmount case and make sure it can support the total weight of your equipment.

- Special Features: Think about any special features you might need, such as shock mounts for sensitive equipment, built-in casters for easy transport, or locking doors for security.

By following these steps, you can confidently choose the right size rackmount case to house and protect your valuable equipment. Using the right size case will ensure proper operation.

8. What are the Different Materials Used for Rackmount Cases?

Rackmount cases are constructed from various materials, each with its own advantages and disadvantages:

- Steel: Steel is a popular choice for rackmount cases due to its strength, durability, and relatively low cost. Steel cases are robust and can withstand rough handling, making them suitable for demanding environments. However, steel is also heavy, which can be a consideration if portability is a major concern.

- Aluminum: Aluminum cases are significantly lighter than steel cases, making them easier to transport. Aluminum is also naturally corrosion-resistant. However, aluminum is generally not as strong as steel and may be more susceptible to dents or scratches.

- Plastic: High-impact plastics, such as ABS or polyethylene, are used to make lightweight and often more affordable rackmount cases. Rotomolded plastic cases are particularly durable and offer excellent impact resistance. Plastic cases are also naturally resistant to corrosion and provide some electrical insulation. However, they may not offer the same level of protection against heavy impacts as steel or aluminum cases.

- Wood with Laminate: Some rackmount cases, especially those designed for audio equipment, are made from plywood or other wood materials and covered with a durable laminate. These cases can offer good protection and a more aesthetically pleasing appearance for certain applications. However, they may not be as robust as metal cases in harsh environments.

Here is a table summarizing the pros and cons of each material:

| Material | Pros | Cons |

|---|---|---|

| Steel | Strong, durable, relatively inexpensive, good EMI shielding | Heavy, susceptible to rust if not properly coated |

| Aluminum | Lightweight, corrosion-resistant, good EMI shielding | Less strong than steel, more expensive than steel |

| Plastic | Lightweight, corrosion-resistant, electrically insulating, often more affordable | Less durable than metal, may not provide adequate EMI shielding without special coatings |

| Wood with Laminate | Good protection, aesthetically pleasing for some applications, can be lighter than steel | Less robust than metal, susceptible to moisture damage if not properly sealed |

The choice of material depends on factors such as the level of protection needed, weight considerations, budget, and the specific application.

9. What are some of the top brands for rackmount cases?

Several reputable brands specialize in manufacturing high-quality rackmount cases. Here are some of the most well-known:

- SKB Cases: SKB is a leading manufacturer of molded cases, including a wide selection of rackmount cases. They are known for their robust rotomolded plastic cases that offer excellent protection against impacts, shocks, and the elements. They offer cases in various sizes, including 2U, 3U, 4U, and larger.

- Pelican-Hardigg: Pelican is renowned for its extremely durable and watertight cases. Their Pelican-Hardigg line includes a range of rackmount cases designed for military, industrial, and other demanding applications. These cases often feature advanced shock mounts and other specialized features for maximum protection.

- Gator Cases: Gator Cases offers a wide variety of rackmount cases, from lightweight models for musicians to heavy-duty cases for industrial use. They have options in various materials, including plastic, wood, and aluminum.

- Road Ready Cases: Road Ready Cases specializes in cases for the audio and entertainment industry. They offer a range of rackmount cases designed for transporting audio mixers, amplifiers, and other equipment.

- Sliger: While primarily known for their high-performance computer chassis, Sliger also offers a selection of well-regarded rackmount computer cases, including 4U and 2U options.

When choosing a rackmount case, it’s always a good idea to consider these reputable brands. They have a proven track record of producing high-quality cases that offer excellent protection and durability. You can find an option that will work for you.

10. How to Properly Pack and Secure Equipment in a Rackmount Case?

Properly packing and securing your equipment in a rackmount case is essential for preventing damage during transport. Here’s a step-by-step guide:

- Use Proper Rack Screws: Always use the correct screws designed for your rack rails (usually 10-32, 12-24, or M6). Using the wrong screws can damage the threads on your equipment or the rack rails.

- Mount Heavier Equipment at the Bottom: When installing multiple pieces of equipment, place the heaviest items at the bottom of the rack case. This helps lower the center of gravity and makes the case more stable during transport.

- Even Weight Distribution: Try to distribute the weight evenly from front to back and side to side within the rack case. This will help maintain balance and prevent the case from tipping over.

- Secure Loose Items: Make sure all components are securely mounted to the rack rails. Use additional brackets or supports if necessary to prevent any movement or vibration during transport.

- Cable Management: Use cable ties or straps to neatly bundle and secure all cables. This will prevent them from getting tangled or damaged and improve airflow within the case.

- Fill Empty Spaces: If there are any empty spaces in the rack, use blank panels or foam inserts to fill them. This will help prevent equipment from shifting during transport and improve the overall stability of the case.

- Secure Lids and Doors: Before moving the case, ensure that all lids, doors, and access panels are securely closed and latched. Double-check that any locking mechanisms are engaged.

- Use Proper Lifting Techniques: When lifting or moving a loaded rackmount case, use proper lifting techniques to avoid injury. Bend your knees, keep your back straight, and use your leg muscles to lift. If the case is very heavy, get help from another person or use a dolly or cart.

- Consider a Ramp: If you frequently need to move your rackmount case up or down stairs or over other obstacles, consider investing in a portable ramp. This will make transport much easier and safer.

By following these guidelines, you can help ensure that your valuable equipment is well-protected and arrives at its destination in perfect working order.

11. Summary

Here are the 10 most important things to remember about rack mount cases:

- Rack mount cases are specialized enclosures designed to house, protect, organize, and transport standard 19-inch rackmount equipment.

- They come in various sizes, typically measured in rack units (U), with common sizes including 1U, 2U, 3U, and 4U.

- Shock mount rack cases offer superior protection against shocks and vibration compared to standard rack cases.

- Key case features to consider include rack unit size, depth, lid style, mounting rails, hardware, casters (wheels), ventilation, cable management, and security.

- 4U rackmount cases provide ample space, expandability, better cooling, and wider component compatibility.

- 2U rackmount cases offer a balance of compactness, versatility, cooling, and cost-effectiveness, making them suitable for many application

- Choosing the right size rackmount case involves measuring your equipment, calculating total rack units, considering future expansion, accounting for depth, and evaluating ventilation, weight capacity, and special feature needs.

- Rackmount cases can be made from steel, aluminum, plastic, or wood with laminate, each offering different advantages in terms of strength, weight, cost, and corrosion resistance.

- Top brands for rackmount cases include SKB Cases, Pelican-Hardigg, Gator Cases, Road Ready Cases, and Sliger.

- Properly packing and securing equipment in a rackmount case involves using proper rack screws, mounting heavier equipment at the bottom, even weight distribution, securing loose items, cable management, filling empty spaces, securing lids and doors, using proper lifting techniques, and potentially using a ramp.

By understanding these key points, you can make informed decisions when selecting and using rack mount cases, ensuring your valuable equipment is well-protected and ready to perform wherever you need it.