Discover OneChassis: A Factory Tour

OneChassis is a leading provider of industrial control chassis solutions. With more than 10 years of experience, our factory covers an area of 8,000 square meters with 95 experienced professionals, including a talented engineering team and a dedicated quality control department. Our product range includes ITX case, NAS case, GPU server case, wall mount case, rack mount chassis, and server chassis, all of which can be customized to meet your specific needs through our OEM/ODM service.

Our advanced CNC component machining capabilities and sheet metal fabrication capabilities allow us to provide quality products and meet the most demanding requirements. Committed to customer satisfaction, we operate in over 100 countries around the world. Choose OneChassis for your IPC needs and experience the benefits of advanced technology, expertise, a full range of customizable chassis options, and cutting-edge CNC part machining capabilities.

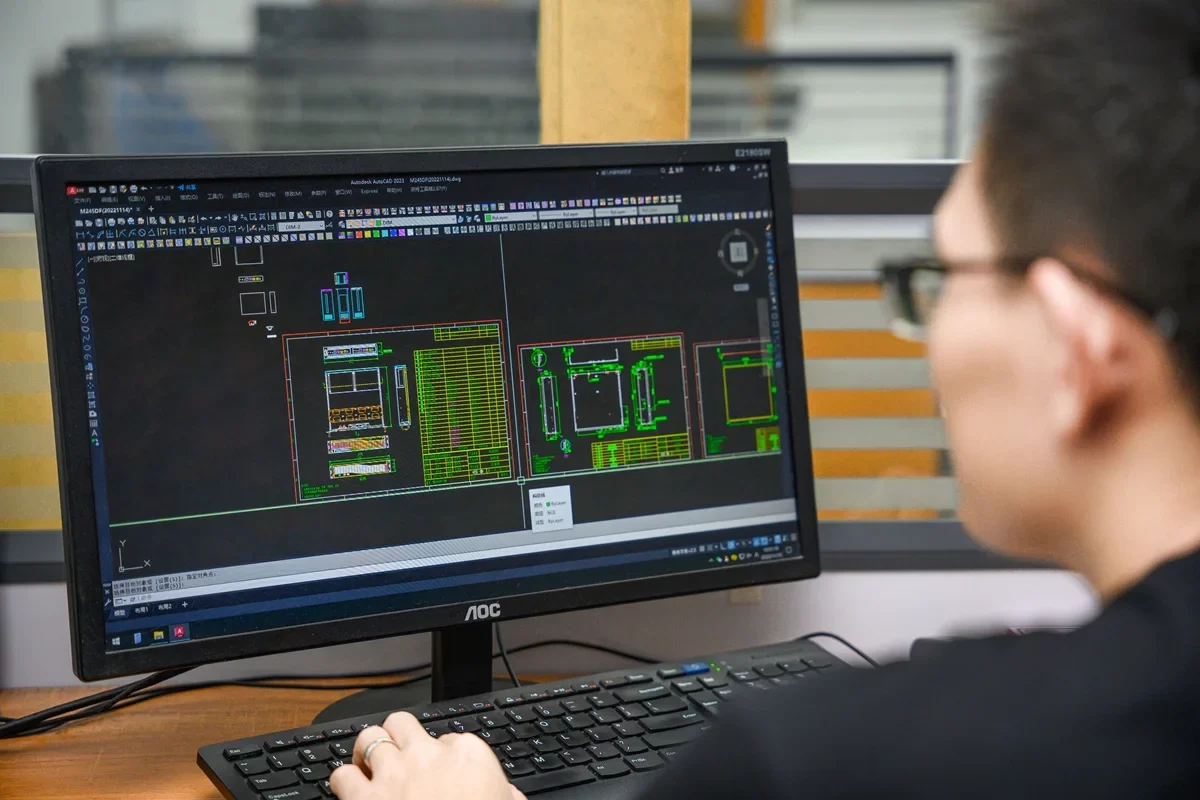

OEM/ODM Manufacturing Solutions

OneChassis is a leading provider of OEM/ODM manufacturing services, offering a full range of support from design to production. Our team of 8 experienced engineers, with over 10 years of expertise in industrial chassis design, is dedicated to providing customized solutions that meet the unique needs of each customer.

With a deep understanding of the structural design of industrial chassis, our engineers work closely with clients to ensure the expected results. Trust OneChassis for all your OEM/ODM manufacturing needs and experience the benefits of a dedicated team of experts and top-quality solutions.

High-Precision CNC Processing

OneChassis boasts a state-of-the-art CNC processing machine lineup, with 10 sets of advanced equipment ready to handle even the largest and most demanding orders. Our commitment to quality and precision extends to the maintenance and upkeep of our machines, ensuring long-term stability and accuracy in every project we undertake.

When you choose OneChassis for your CNC processing needs, you can be confident in our ability to deliver on-schedule, high-precision results. Trust us to bring your vision to life, with the power and precision of our cutting-edge CNC processing machines.”

Efficient and Accurate NC Milling

OneChassis offers a wide range of CNC milling machines, each capable of producing precise and accurate results. Our state-of-the-art machines are programmed to handle a variety of processing needs, ensuring efficient and reliable results every time.

Choose OneChassis for all your NC milling needs and experience the benefits of advanced technology and expertise. With our diverse range of processing equipment, we are fully equipped to meet the demands of any project, big or small.

Medium-speed Wire cut Electrical Discharge Machining

Our facility is equipped with 5 advanced Medium-speed Wire Cut Electrical Discharge Machining systems, capable of delivering precise results in even the most demanding machining operations.

Punch

Our facility is equipped with 12-punch presses of varying tonnages, allowing us to handle a wide range of stamping processing needs with ease. To ensure the longevity of our equipment and the safety of our operations, we perform daily and regular maintenance on all punch presses.

High-Speed Punching Machine – Precision Continuous Mold

OneChassis is equipped with advanced High-Speed Punch systems featuring precision continuous molds and automatic servo-feeding equipment. This setup enables efficient and precise automatic continuous stamping of parts, ensuring high production and dimensional accuracy.

CNC punch

Our CNC digital punching machines are equipped with advanced control systems and high-precision molds, providing precise and efficient processing for various materials. Our maintenance program ensures consistent processing accuracy and prolonged machine life.

CNC Bending for Precise Shaping

Our 12 CNC bending machines allow for accurate shaping to meet your specifications. With the machines located near the conveyor belt, production becomes more efficient, reducing the need for manual handling and storage space for work in progress.

Tapping Machine, Riveting Stud Machine

Both tapping and riveting machines are specialized tools used in manufacturing operations to increase efficiency and streamline the production process. Tapping machines allow multiple holes to be drilled at once, saving time and increasing production speed. The riveter is mounted near the conveyor belt and helps reduce handling and storage requirements for the product being processed. By using these tools, a more efficient and cost-effective production process can be achieved.

Assembly Line

There are currently 3 assembly lines in operation at the plant, one of which is designated as a confidential line and is located in a separate shop for customers who require it. This line and the other two are closely monitored by three Quality Control (QC) personnel to ensure that the assembled products meet the required quality standards. With this system, the plant can efficiently produce high quality products and meet the confidentiality requirements of our customers.

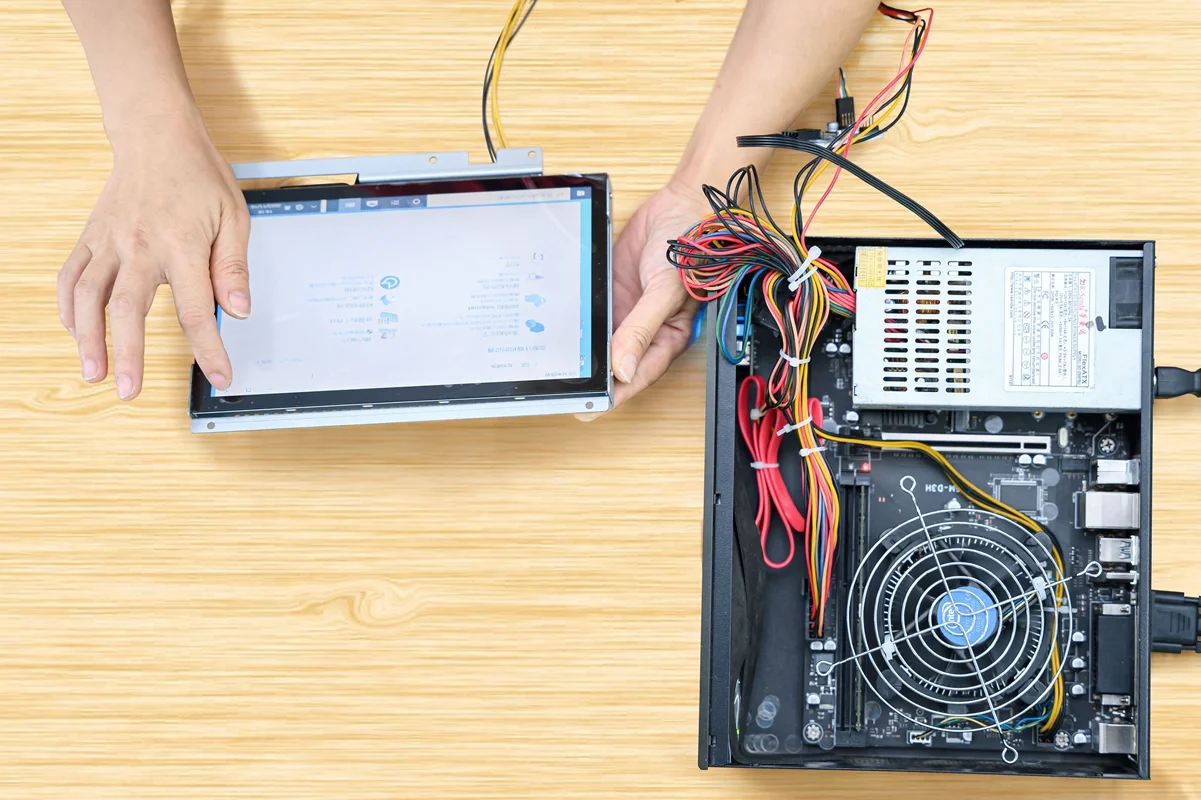

Product Tests

Functional testing of integrated systems can be done online by arrangement with interested parties. This allows customers to verify that the system works as expected and meets their requirements. During this process, different aspects of the system are tested, such as usability, performance, and compatibility, to ensure that it functions properly and meets the necessary standards.

Package

Immediate packing after the assembly line can reduce the risk of damage to the product during handling.

The standard shipping method is neutral carton packaging, but customized packaging with a customer’s logo is also available with a minimum order quantity of 300 pieces. If you’re interested in this personalized service, please contact Us.

Warehouse

Our warehouse is equipped to store and manage standard products that are ready for immediate delivery. The warehouse is well-organized, well-lit, and ventilated, and has the necessary safety facilities to ensure a suitable environment for storing products. There is a dedicated team of personnel to manage the warehouse, who is responsible for conducting regular inventory checks, monitoring incoming and outgoing shipments, and ensuring the overall efficiency and organization of the storage facility.

Punch Mold

We use mold production for conventional products and common parts to ensure efficiency and precision. To maintain the precision and performance of the molds, they are regularly inspected and maintained according to their technical status. The mold maintenance cycle is divided into three categories (A, B, and C) based on the degree of vulnerability of the mold. For example:

- Type A molds (drawing die, flanging die, shaping die, cladding die) need to be maintained once after 6000-7000 strokes.

- Type B molds (trimming and punching dies) need maintenance once every 5000 strokes.

- Type C molds (a simple shape with a large one-time production volume) need maintenance once after 7000-10000 strokes.

A “Mold Maintenance Plan” is formulated based on these principles and maintenance is carried out in a comprehensive manner.

Meeting

The company holds a variety of meetings on a regular basis. These meetings include production meetings before and after shifts, production scheduling meetings, quality analysis meetings, safety meetings, and project progress discussions. The company also conducts problem analysis and improvement meetings as needed. Annually, the company holds an annual meeting and commendation meeting to boost team morale and set the direction for the team. These meetings ensure that everyone is on the same page, updates are communicated effectively, and that any issues are addressed in a timely manner.